Alumina Extrusion: Unveiling the Science Behind It

Comprehensive Analysis of Alumina Extrusion: Processes, Benefits, and Challenges

In manufacturing today, alumina extrusion functions as an essential process for designing versatile and precise components.

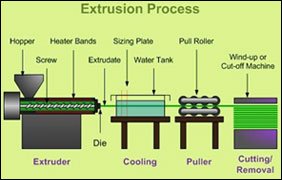

The method of alumina extrusion uses heated alumina which is forced through a die to form complex shapes with precision and consistency.

Foundation of Alumina Extrusion

At its core, alumina extrusion utilizes the application of pressure to form raw alumina into required profiles, ensuring high industry standards.

The extrusion process requires alumina to be well-conditioned to reach specific mechanical properties and intended surfaces.

Processes and Methods in Alumina Extrusion

There are multiple methods employed in alumina extrusion, each with its unique advantages and specific applications.

Methods like direct, indirect, and impact extrusion allow manufacturers the flexibility to choose based on alumina's properties and the final design necessities.

Real-World Uses of Alumina Extrusion

Alumina extrusion is indispensable in many industries, spanning automotive, aerospace, and construction, offering durable and lightweight product solutions.

In electronics, the use of alumina extrusions for casings and heat sinks leverages its high thermal conductivity and electrical insulating properties, boosting operational efficiency.

Navigating the Complexities of Alumina Extrusion

Despite the numerous benefits, alumina extrusion faces challenges such as die wear, thermal management, and achieving consistent quality across large scale production.

Manufacturers combat these hurdles by deploying improved die materials, cutting-edge cooling technologies, and automation processes for ensured output quality.

Future Trends in Alumina Extrusion Technologies

As technology advances, the field of alumina extrusion is becoming increasingly efficient, adopting digital manufacturing techniques like 3D printing and AI-driven process controls.

These advancements aim to curtail waste and boost the exactness of extruded profiles, offering expanded industrial applications for alumina.

Final Remarks on Alumina Extrusion

Alumina extrusion remains a cornerstone in the manufacturing landscape, delivering indispensable solutions for complex production needs.

As developments continue and research targets its capability enhancements, alumina extrusion is likely to take a larger stake in the future manufacturing picture.